- +91 9029516529 / 22 67437274

- GSTIN : 27CDQPP2558D1Z7

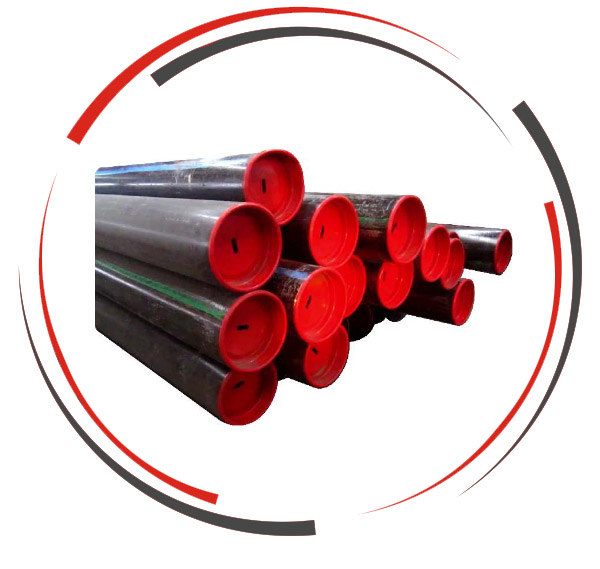

SEAMLESS, WELDED, ERW & EFW

SPECIFICATION : ASTMA106 Gr. A & B, ASTM A53 Gr. A & B,

ASTM A333 GR.1, 6 & 3, API 5L Gr. B to API SL X80 etc.

GRADE : ASTMA335 GR. P1, P5, P11, P12, P22, API 5L GR. A & B BS 3059,

3601, 3602, 3603, 3604, 4360, DIN ST 33, 34-2, 35, 37.2, 42.3, 45, 52,

IS-1239 PART 1, IS 3589 API 5L X42 PSL 1 & PSL2, API5L X46 PSL1

& PSL2, API 5LX52 PSL1 & PSL2, APISL X56 PSL1 & PSL2, API5L X60 PSL1 &

PSLI2, API 5L X65 APL1 & APL2, API SL X70 PSL1 & PSL2, API5L X80 PSL1

& PSL2 etc.

Karwad Steel and Engineering Company is a dominant manufacturer and supplier of a comprehensive range of pipes, tubes, fittings and flanges and many more products. Renowned for delivering complete solutions, we cater to wide range of industries. We specialize in providing both standard and custom stainless steel pipes and carbon and alloy pipes and tubes customized as per requirements, regardless of size, length, material requirements or finishing. We have a highly skilled team that works diligently to fulfill planned orders with precision. Additionally, our manufacturing unit is equipped with top tier infrastructure, ensuring efficient and high quality production.

Carbon and alloy steel pipes and tubes are critical materials in various industrial applications, characterized by their robust mechanical properties and versatility. The manufacturing processes for these pipes and tubes include seamless and welded methods, with the latter further categorized into Electric Resistance Welded (ERW) and Electric Fusion Welded (EFW). Seamless pipes are produced by extruding solid steel billets, resulting in a product that is free from weld seams which enhances its strength and reliability under high pressure conditions. In contrast, welded pipes are formed by joining flat steel plates with ERW utilizing electrical resistance to create the weld, while EFW employs a fusion process to ensure a strong bond.

The specifications for these pipes and tubes are governed by various standards including ASTM A106 Grades A and B, ASTM A53 Grades A and B and ASTM A333 Grades 1, 3 and 6 among others. These specifications ensure that the materials meet the necessary requirements for pressure and temperature applications. Additionally, API 5L specifications range from Grade B to X80, catering to the needs of the oil and gas industry, where high strength and durability are paramount.

In terms of grades, carbon and alloy steel pipes and tubes are available in a variety of classifications such as ASTM A335 Grades P1, P5, P11, P12 and P22, which are designed for high temperature service. Other notable grades include API 5L Grades A and B as well as BS 3059, DIN ST 33 and IS-1239 Part 1. These grades are essential for ensuring that the pipes and tubes can withstand specific environmental conditions and mechanical stresses.