- +91 9029516529 / 22 67437274

- GSTIN : 27CDQPP2558D1Z7

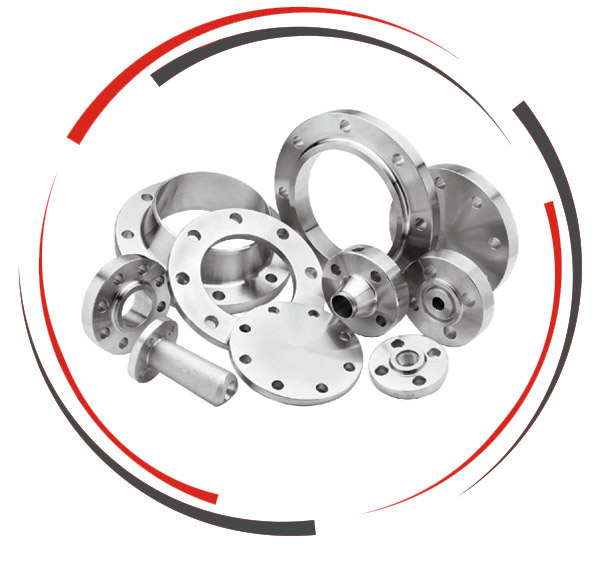

Looking for top-quality stainless steel flanges? As a trusted stainless steel flanges manufacturer and exporter in Mumbai, India, we specialize in producing and supplying flanges that offer unparalleled performance and durability for a variety of industrial applications. Our stainless steel flanges are known for their strength, corrosion resistance, and versatility, making them ideal for both domestic and international projects.

As a leading flange supplier in India, we are committed to providing products that meet the highest standards of quality. Here’s why our stainless steel flanges are the preferred choice of engineers and industries :

Superior Quality Material : We use high-quality stainless steel alloys that ensure excellent strength, durability, and resistance to wear and tear.

Wide Range of Sizes : Our flanges are available in a variety of sizes and pressure ratings to meet specific application needs.

Customization Options : We offer custom designs and sizes to suit your specific requirements, ensuring a perfect fit for your projects.

Competitive Pricing : Our products are competitively priced, offering superior value without compromising on quality.

International Standards : We adhere to international quality standards, ensuring that our flanges are safe, reliable, and long-lasting.

Stainless steel flanges provide several key advantages, making them ideal for a wide range of industrial applications :

Corrosion Resistance : Stainless steel flanges are highly resistant to rust and corrosion, even in harsh environments. This makes them ideal for industries that deal with water, chemicals, or extreme weather conditions.

High Strength : These flanges have excellent tensile strength, making them suitable for applications that involve high-pressure and heavy-duty workloads.

Durability : Stainless steel is a tough and long-lasting material, which makes stainless steel flanges highly durable and capable of withstanding wear and tear over time.

Easy Maintenance : Due to their smooth surface, stainless steel flanges are easy to clean and maintain, making them a popular choice in hygienic environments like food processing or pharmaceuticals.

Temperature Resistance : Stainless steel can endure both high and low temperatures, which makes these flanges ideal for applications in industries like oil & gas, chemical processing, and HVAC systems.

Aesthetic Appeal : Stainless steel flanges have a shiny and polished appearance, adding to their aesthetic value, which is essential in decorative applications and high-visibility installations.

Our stainless steel flanges are used in a wide variety of industries and applications, including :

Oil and Gas : Used to connect pipes in oil refineries, drilling rigs, and pipelines, providing a leak-proof and durable seal.

Chemical and Petrochemical Industry : Essential for safely transporting chemicals, gases, and other hazardous materials under high pressure and extreme temperatures.

Water Treatment Plants : Stainless steel flanges are used to connect pipes and equipment in water treatment facilities due to their corrosion resistance and durability.

Food and Beverage Industry : They are used in food-grade applications where hygiene and corrosion resistance are vital.

Pharmaceuticals : Stainless steel flanges play a critical role in the pharmaceutical industry, where cleanliness and resistance to contamination are essential.

Construction : Used for piping systems in buildings and infrastructure projects, stainless steel flanges ensure strength, safety, and long-lasting performance.

HVAC Systems : Stainless steel flanges are essential in HVAC systems where temperature fluctuations and the need for reliable seals are a concern.

As an experienced stainless steel flanges exporter, Karwad Steels & Engineers has built a reputation for providing products that exceed customer expectations. We focus on :

Advanced Manufacturing Techniques : Our flanges are manufactured using the latest technologies to ensure precision and consistency.

On-Time Delivery : We understand the importance of deadlines in industrial projects, which is why we are committed to on-time delivery, both domestically and internationally.

Quality Assurance : Every stainless steel flange undergoes rigorous quality testing, ensuring it meets the highest standards for strength, durability, and performance.

Get in Touch with the Leading Stainless Steel Flange Manufacturer in India

Looking for durable and reliable stainless steel flanges? Whether you need a standard or custom design, we have the expertise and resources to fulfill your requirements.

Contact us today for a quote or more information about our products.

SLIPON (SORF), SOCKETWELD (SWRF), BLIND (BLRF),

WELDNECK (WNRF), SCREWED (SERF), LAPPED (LJFF),

WELDNECK RING JOINT (WNRTJ)

RANGE : FORGED FLANGES: 1/2" (15 MM) NB to 24" (600 MM) NB

PLATE FLANGES : 1/2" (15 MM) NB to 48" (1200 mm) NB

DIMENSIONS :-

ANSI B16.5 & BS1560 : CLASS 150 #, 300 #, 600 #, 900 #, 1500 #

DIN : 2527, 2573, 2576, 2633, 2634, 2635, ND-6, ND-10, ND-16, ND-40

BS10 : TABLE D, E, F, H, J,

BS4504 : Table ND-6, ND-10, ND-16, ND-25,ND-40

1$6392 : TABLE 5, 11, 17, IS 1538, MSS-SP44

STAINLESS STEEL

ASTM A 182 F 304, F 304L, F 304H, F 309, F 310, F 316, F 316L,

F 316 TI, F 317, F 317L, F 321, F 347,

ALSO IN PLATE ASTM A 240 TP 304, 304L, 316, 316L, 317, 317L

CARBON STEEL & ALLOY STEEL

ASTM A 105, ASTM A 182 F5, F9, F11, F22, ASTMA 350 LF1. LF2,

LF5 ALSO IN PLATE IS-2062, GR. A, B, C, ASTMA 516 GR. 60

GR. 70 SOCKET WELD & THREADED

OTHERS : Nickel & Nickel Alloys, Inconel, Monel, Hastelloy,

Cupro-Nickel, Titanium, Duplex, Super Duplex etc...