- +91 9029516529 / 22 67437274

- GSTIN : 27CDQPP2558D1Z7

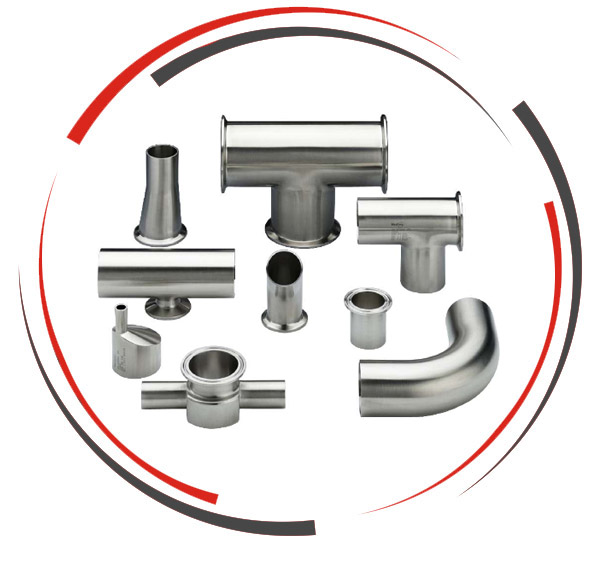

TC BEND, TC TEE, TC REDUCER, TC UNION, TC CLAMPS,

TC LINER (FERRULES), TRI-CLOVER STANDARD FITTINGS IS WIDELY

USED IN PHARMACEUTICALS & FOOD INDUSTRIES FOR ITS EASILY

OPENING & CLEANING FACILITIES. IT CONSISTS OF TWO LINERS

(FERRULES) & CLAMPS WHICH HOLDS BOTH THE LINES TOGETHER.

GASKET IS HOUSED BETWEEN THE LINES TO GIVE LEAK PROOF

SEALING.

RANGE : ½" (15MM) to 12" (300MM) (SUITABLE FOR OD &NB SIZE PIPE)

GRADE : AISI 304, 316, 316L

STANDARD : ISO, ASME BPE Standard.

FINISH POLISHED : ELECTRO POLISHED / MIRROR / MATT FINISH

Karwad Steel and Engineering Company is recognized as a top-rated manufacturer and supplier of an extensive range of pipe fittings and flanges available in materials such as Stainless Steel, Alloy Steel, Carbon Steel including valves,fasteners,round bars and other associated products. We display a modern infrastructure complemented by a dedicated and motivated workforce committed to achieving total quality control. Our production unit oversees every aspect of the process, from design to finalization, all managed by our skilled technical staff. At Karwad Steel and Engineering Company, we place continuous emphasis on modernizing our manufacturing facilities, prioritizing technological innovation.

Tri-Clamp (T.C.) fittings, also known as bio-pharmaceutical fittings, are essential components in the pharmaceutical and food industries, recognized for their ease of assembly and cleaning. These fittings consist of components such as TC bends,tees,reducers,unions,clamps and liners which work together to create a sanitary solution for transporting liquids and gases while minimizing contamination risks. The design features two ferrules held together by clamps, with a gasket placed in between to ensure a leak proof seal, thereby enhancing efficiency. Available in a size range from ½" 15 mm to 12" 300 mm for both outside diameter and nominal bore size pipes, these fittings are manufactured from high quality AISI 304,316 and 316L stainless steels, offering excellent corrosion resistance. They comply with industry standards such as ISO and ASME BPE ensuring reliability for high purity applications. Additionally, various polished finish options such as electropolished, mirror and matt finishes, allow for customization based on specific cleaning requirements,thereby making TC fittings an ideal choice for maintaining stringent hygiene standards in critical applications.